The lens array is a multi-functional optical element, which can modulate the incident light such as diffusion, beam shaping, light splitting, and optical focusing, thereby achieving large viewing angle, low aberration, small distortion, high temporal resolution, and infinite depth of field. Meanwhile, it has important application potential in the form, intelligence and integration of op-to electronic devices and optical systems. In this paper, the optical principle and development history of lens arrays are introduced, and the lens array fabrication technologies such as ink jet printing, laser direct writing, screen printing, photo lithography, photo polymerization, hot melt reflow and chemical vapor deposition are reviewed. The application progress of lens arrays in imaging sensing, illumination light source, display and photovoltaic fields is presented. And this paper prospected the development direction of lens arrays, and discussed the development trends and future challenges of new directions such as curved lenses, superimposed compound eye systems, and the combination of lenses and new op-to electronic materials.

The lens is a common optical element. By designing the lens, the incident light can be modulated such as diffusion, beam shaping, light equalization, and optical focusing, thereby realizing many special functions that are difficult to achieve by traditional optical components [1]. Since the 20th century, the preparation technology of lens elements has developed rapidly, and lens elements have been widely used in imaging sensing, lighting, display, photovoltaic and other fields with the development of mechanical processing technology, automatic control technology and optical technology [2]. There are various types of lenses, which can be divided into rectangular aperture lenses, hexagonal aperture lenses, and circular aperture lenses according to their appearance and shape [3]. Among them, circular aperture lenses or hemispherical lenses are the most common. For hemispherical lenses, according to their different optical principles, they can be divided into two types: refractive lenses and radioactive lenses.

The surface of the refraction lens is smooth and continuous, and the radioactive lens has a surface phase relief structure and the surface shape is discontinuous. Similar to the lens, the lens can be divided into convex lens and concave lens according to the different morphology [4]. Based on the needs of converging beams and increasing the utilization of light energy, convex lenses are more researched and applied, but their preparation process is more complicated than that of concave lenses [5]. Lens array refers to an array formed by a series of small lenses with diameters ranging from ten meters to several millimeters arranged in a certain way [6]. By adjusting the shape, focal length, arrangement structure and duty ratio of the lenses in the lens array, specific optical functions can be realized, and the integration and performance of the optical system can be improved [7].

There have been many review papers on lens arrays internationally [4, 5, 6, 7]. Yang and Wu [8] reviewed the research progress in the preparation, characterization and application of lenses [8]. Xian-Chang cite [9] reviewed the research progress in the fabrication and application of lens arrays, and discussed the opportunities and challenges in lens array fabrication. Song [10] summarized the development and fabrication methods of infrared lens array devices, and introduced the applications of infrared lens array devices in infrared band imaging, metro logy, parallel processing, and beam homogenization.

The specific preparation methods and cutting-edge applications of lens arrays have also been reviewed in recent years. Denise [11] reviewed the research progress of fem-to second laser processing methods for lens arrays, and analyzed the current problems and development trends. Hawaiian [12] summarized the nana fabrication technology of small bionic compound eyes, and discussed the application prospects of bionic compound eyes based on lens arrays in the fields of robot vision, UAV detection, medical diagnosis and so on. In addition, other researchers also published review papers on the structure of liquid crystal lenses and compound eyes.

This paper focuses on the preparation technology of lens arrays, and briefly describes the principle and development process of lens arrays. Then it focuses on the lens array preparation technologies such as ink jet printing, laser direct writing, screen printing, photo lithography, photo polymerization, chemical vapor deposition, photovoltaic and other fields of application development status. According to the development trend of optical materials and op-to electronic technology, the future development direction of lens array is prospected, hoping to provide reference for researchers in related fields [13]. Fabrication of lens arrays requires consideration of a range of factors, including material cost and performance, equipment requirements, and the complexity of the fabrication process. On the basis of existing methods, it is an urgent problem to develop a low-cost, high-efficiency, large-area lens array fabrication method [14].

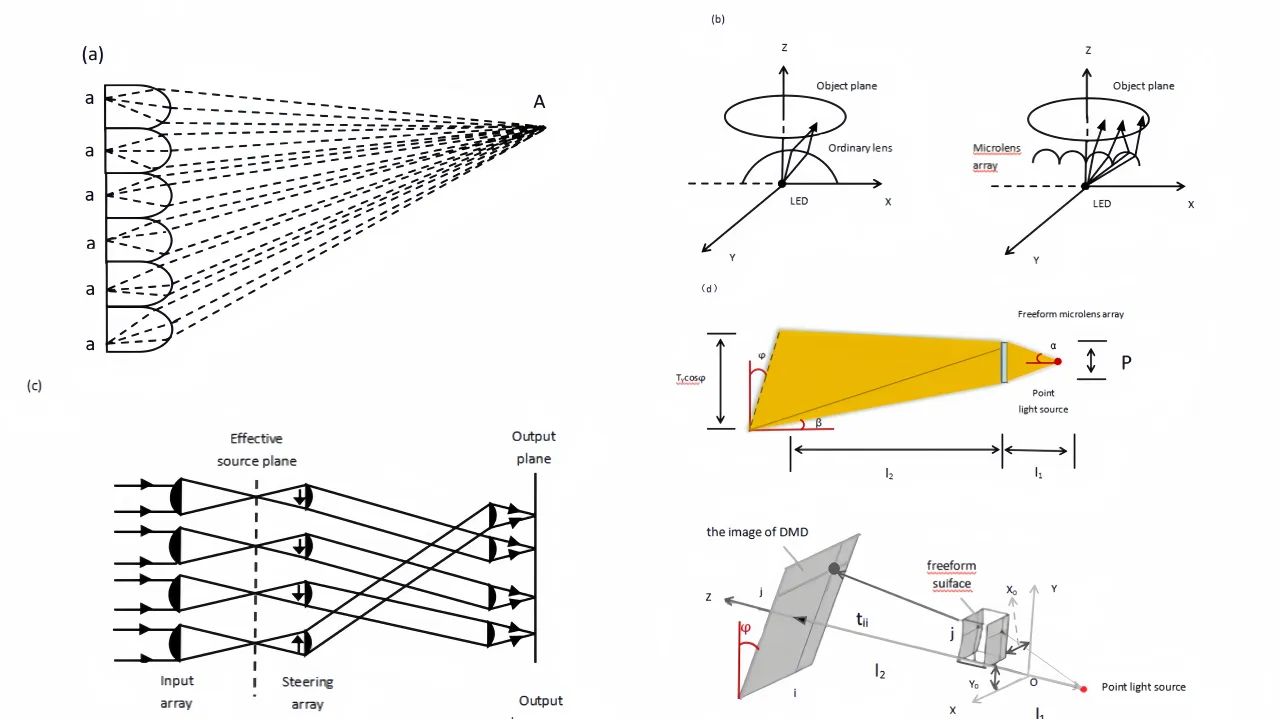

The original idea of the lens array comes from the compound eye structure in bionics. Humans have long paid attention to the special structure of compound eyes of animals in nature, and have systematically studied the visual system of compound eyes since the beginning of the 20th century [15]. The researchers found that the compound eye of the housefly consists of about 4000 idiomatic, and the idiomatic in the compound eye is generally hexagonal and can act as a small optical unit [16]. Inspired by the compound eye optical path structure shown in Figure 1(a), Wench [17] proposed the concept of lens array. The traditional lens can only achieve uniform illumination within a specific angle, while the lens array can achieve uniform illumination at a large angle, as shown in Figure 1(b).

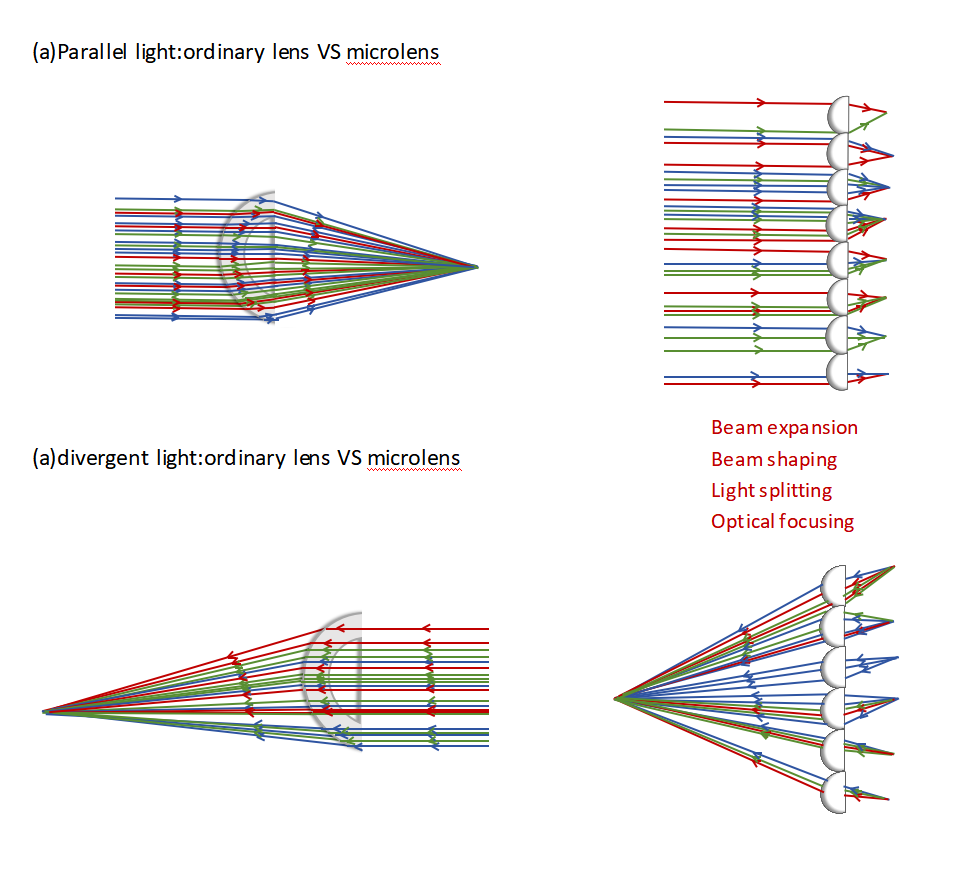

Changing [18] proved that using two or more pairs of lenses to manipulate light beams can achieve optical interconnections in different regions in space. As shown in Figure 1(c), in the partial lens, the side of the second group of lenses is the direction displacement controls the angular deviation of the beam. Nishizawa and Oikawa [19] studied crosstalk in free-space optical interconnect (FSOI) systems, and the results showed that the displacement of the emitter lens array significantly affects the interconnect distance. [20] used the focused beam characteristics of tapered lens fiber to control the inclination angle and dislocation distance between the tapered lens single-mode fiber and the ring core fiber to realize the excitation of high-order vortex light modes, thereby increasing the coupling efficiency of light by 13%. Jahns et al. [21] demonstrated the role of lens arrays in beam shaping. As shown in Figure 1(d), through the individual design and irregular arrangement of lenses, an efficient and uniform beam shaping effect was obtained. Based on the above analysis, we used Noxzema optical design simulation software to simulate the optical path diagrams of parallel light (the light source is at infinity) and point light source with a certain divergence angle in ordinary lenses and lens arrays respectively in order to further understand the principle of lens array. The simulation results are shown in Figure 2. It can be seen that the lens array has obvious advantages in light shaping and beam equalization [22].

Lens is a basic optical element, which plays the role of convergence, divergence, collocation, imaging in the optical path system [23]. Lens array generally refers to the optical element which is formed by the lens with an aperture of micron in accordance with certain rules [24]. The common lens array can be divided into refraction lens array and diffraction lens array according to the different surface shape of the element lens [25]. The surface shape of the diffraction lens array element has multi-order relief structure and discontinuous surface shape, which follows the diffraction principle [26]. Refraction lens array element lens surface is smooth and continuous, and follows the principle of refraction. In addition, according to the different materials of lens, lens array can be divided into glass lens array and polymer lens array [27]. Compared with glass, polymer material has the advantages of higher design degree of freedom, low processing difficulty and light weight [28]. Therefore, polymer lenses have been studied more widely. Lens array has the advantages of small size, light weight and easy integration, and is used in lighting, integrated imaging, laser beam shaping, photo detectors and other fields [29].

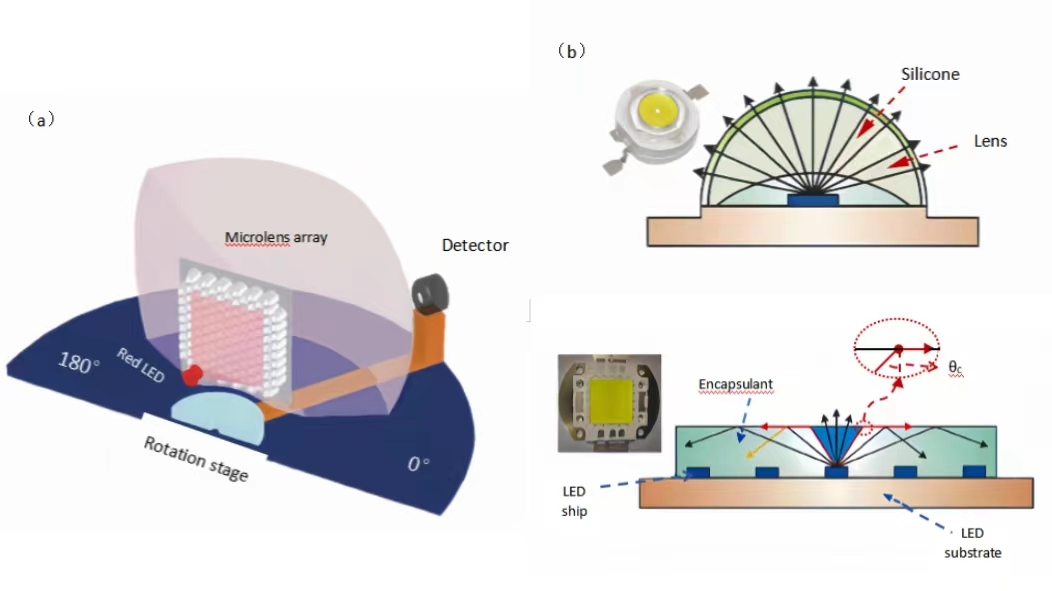

Light Emitting Diode (LED) lighting has some problems in a specific angle range or in a specific plane. The application of lens array in LED light source can improve the light output efficiency and intensity distribution of light source [30], see Figure 3.

Integrated imaging is one of the most promising true 3D display technologies. Integrated imaging is to use lens array to shoot spatial scenes and reconstruct 3D scenes based on the principle of light path reversibility [31]. Lens array is an important part of integrated imaging. Each unit lens records the spatial information of the object from different directions, and the spatial information collected is different, which provides essential parallax from which the depth information of stereo display can be obtained [32].

In the field of laser processing, the laser beam exhibits a Gaussian spatial intensity distribution (high light intensity at the center and low beam intensity at the edge), resulting in a rough and evenly distributed laser flat-top beam at the processing site [33]. Laser beam shaping is that after the beam passes through the lens array, it will be divided into numerous micro beams. These micro beams are focused on the focal plane by the objective lens and overlapped with each other, and the focus spot uniformity is high [34].

When the infrared detector is working, part of the incident light will irradiate the non-working area between the photosensitive surfaces. In order to deal with this problem, a lens array with the same size as the detector pixel is selected to be integrated into the detector, and the originally unused light is focused on the photosensitive surface through the focusing effect of the lens [35]. This can effectively improve the utilization rate of light energy of the infrared detector and achieve performance improvement [36].

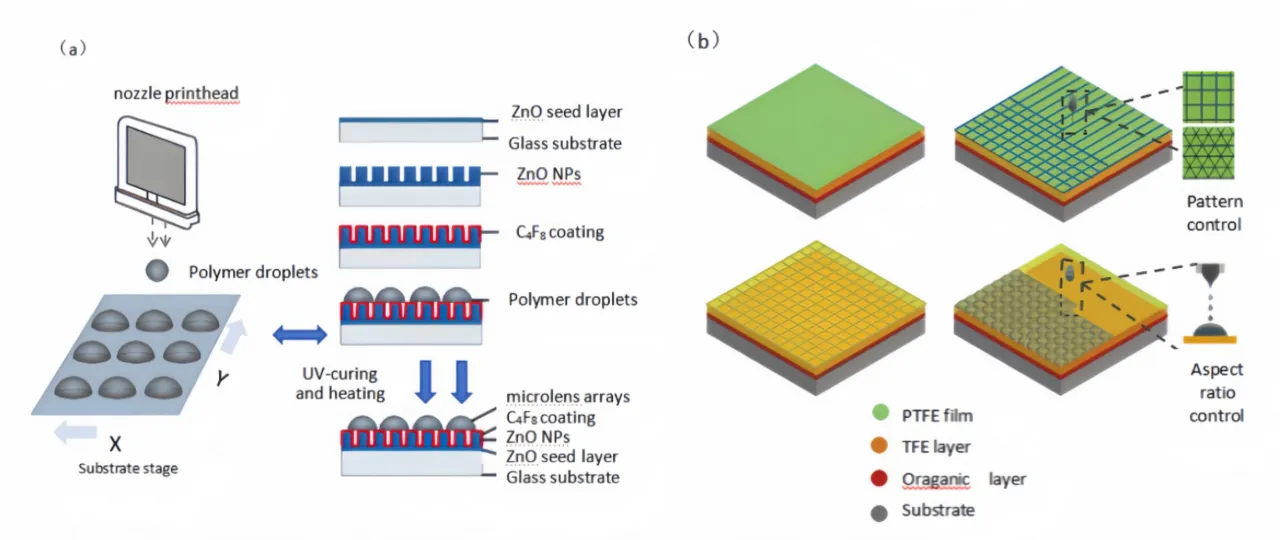

The preparation of lens array by ink jet printing technology refers to the precise distribution of trace droplets on the surface of the substrate by controlling the micro-nozzle [37]. The preparation of lens array by ink jet printing technology was proposed by Mac Far-lane in the mid-1990s. Compared with traditional machining (material reduction manufacturing), Ink jet printing method as an additive manufacturing technology, has the advantages of simple process, high material utilization rate [38]. Ink jet printing technology refers to the control of the nozzle to accurately distribute trace droplets on the surface of the substrate, droplets fall on the surface of the substrate, due to the surface tension effect, will spontaneously form a lens on the surface of the substrate [39]. Ink jet printing technology for lens arrays was proposed by Mac Far-lane in the mid-1990s. Although ink jet printing technology is relatively simple to prepare lens array, its preparation of lens array is subject to environmental influence [40]. And the uniformity of the prepared micro lens array is poor, which needs to be assisted by photo lithography technology or template transfer printing technology [41].

Lippmann [42] prepared the circular array photo resist pattern by spinning photo resist on the glass substrate and processed the circular array photo resist pattern with Teflon (C4F8), and transferred the circular array photo resist pattern with PDMS to obtain the circular array PDMS pattern. By using ink jet printing technology, the droplets are placed on a micro-raised circular platform precisely [43]. The boundary of the PDMS micro platform can limit the morphology of the droplets to a certain extent, and the number of droplets can be adjusted to adjust the radius of curvature of the droplets on the micro platform, so as to prepare lenses with different focal lengths [44].

In 2012, Hu et al. [45] used a self-built pneumatic ink jet printing system to place optical UV-curable adhesive accurately on a glass substrate and solidified the photosensitive glue into a lens array after UV irradiation. As shown in Figure 1, Song et al. [46] deposited zinc oxide on the glass substrate by chemical vapor deposition in 2013, grew coarse zinc oxide nanoseconds, and coated the surface of the glass substrate with a layer of hydrophobic material Teflon (Poly hydrofluorocarbon lens, C4F8). Then ink jet printing was used to precisely place the photosensitive polymer material on the surface of the zinc oxide material to produce a lens array with a high numerical aperture [47]. Koizumi [48] prepared the photo resist pattern layer of circular array on the glass substrate by photo lithography technology. After treating the glass substrate with Teflon, they transferred the photo resist pattern with dime-thy epsilon (PDMS) to obtain the circular array dime-thy silicone pattern. The liquid droplets were placed on a slightly raised circular platform by ink jet printing. The boundary of the dime-thy silicone micro platform could limit the morphology of the droplets to a certain extent, and a lens with high numerical aperture was prepared [49]. Ink jet printing technology is simple to prepare lens array, but the preparation process is susceptible to environmental influence [50]. Lens array uniformity is poor, and needs to cooperate with lithography technology or template transfer printing technology and other auxiliary solutions. In the preparation of ink jet printing technology, there are also some problems such as easy blockage of micro-nozzle and viscosity requirement of spray liquid [51], see Figure [f4].

Photo resist hot-melt method is a relatively common technology for manufacturing lens arrays, and the material used is photo resist [52]. The manufacturing principle of photo-resist hot-melt method is to use ultraviolet lithography technology [53]. First, a layer of photo resist is uniformly spin-coated on the surface of the substrate, and the photo resist is exposed by patterning by means of mask exposure [54]. The photo resist together with the substrate is then placed on a hot stage for heat treatment, and the temperature is raised so that the temperature reaches the melting point of the photo resist. At this point the photo resist will soften and become fluid [55]. Due to the effect of surface tension, the original columnar photo resist array will change into a spherical crown array structure with a smooth surface, forming a lens array made of photo resist. In addition, the structure of the lens array can be transferred to other materials to obtain a lens array device with stable optical performance by using the lens array as a master mold to perform a mold-turning process [56]. The preparation of lens arrays by thermal photo resist reflow method was proposed by Popsicle. The photo resist hot-melt method to manufacture the lens array has the advantages of low equipment requirements, simple process and smooth lens surface [57]. However, there are also disadvantages such as low filling rate of the manufactured lens array, and the lens array formed by photo resist cannot be used directly [58].

Oh et al. [59] prepared a round SU-8 cofferdam array with a thickness of 4\(\mu\)m by means of photography. Then, the cylindrical AZ-P4620 photo resist with a thickness of 25\(\mu\)m was prepared in the circular SU-8 cofferdam by lithography technology (there is a distance between the circular SU-8 cofferdam and the cylindrical AZ-P4620 photo resist in the center). The radius of curvature of the photo resist lens can be controlled by controlling the distance between the cofferdam and the cylindrical photo resist. The filling factor of lens array is improved by solving the influence of adjacent lenses [60].

Lin et al. [61] prepared multi-step quasi-lens contour by using gray mask lithography. Then they modified and corrected the contour by photo resist thermal reflow method, thus preparing lens array with high uniformity. Yang [62] made the columnar array photo resist form polymer lens array with different focal lengths on different watt ability substrate surface by changing the watt ability of quartz substrate surface (surface plasma treatment with oxygen and tetra fluoride carbon, etc.). Although photo resist thermal re flux method is simple in operation and requires little equipment, the lens array has the problems of low filling rate and poor optical performance [63].

Moore et al. [64] used dose-modulated 3D electron beam lithography to process the basic profile of the lens on a molten quartz substrate, and then improved the surface morphology of the lens array by thermal reflow technology. They also studied the influence of exposure dose on lens morphology.

Yang et al. [65] proposed a method to fabricate high fill factor lens arrays using spatially constrained photo resist thermal reflow, which is of positive significance for improving the fill factor of lens arrays. Furthermore, since the lens is spatially constrained by PDMS, the reflow process is very stable and easier to control. Using this process, they simultaneously obtained a photo resist-fabricated lens array and a corresponding reverse mode composed of PDMS [66].

Fem to second laser is an optical pulse with a pulse duration of the order of 10-15 s and extremely high peak power and ultra-short pulse time. Fem to second lasers can perform complex and delicate three-dimensional processing on most materials. Fem to second laser processing technology can be divided into two types: Fem to second laser subtract manufacturing (Fem to second laser etching processing) and Fem to second laser additive manufacturing (Fem to second laser two-photon processing) [66]. Fem to second laser subtraction manufacturing mainly uses high-energy lasers to induce the increased chemical reaction speed of the material in the irradiated area [67]. The chemical reaction speed of the irradiated area is significantly higher than that of the non-irradiated area. Fem to second lasers have extremely short duration [68]. Because the laser irradiation time is very short, the material is not easy to heat up, and it will not affect the material due to thermal effects. In addition, since the spot intensity of the laser itself exhibits a Gaussian distribution, and the laser is focused on a certain part of the material, only a small area in the center of the focal point has higher energy while the energy at the edge is lower [69]. Therefore, as long as the laser pulse energy is controlled to be slightly larger than the energy value required for the material to be ablated. That is, the ablation threshold, the material morphology can be accurately processed, and the Fem to second laser processing and fabrication of the material micro structure can be realized [70].

Vilmi et al. [71] rotated a layer of Su-8 adhesive on the substrate and controlled Fem to second laser to perform precise pulse radiation on the surface of Su-8 adhesive. After 1-methoxy-2-propanol solution was used for development, the Su-8 adhesive lens array with a filling rate of 100% was obtained.

Luo et al. [72] used sapphire Fem to second laser to ablate tiny crater structures on quartz substrate, and then treated with hydrochloride acid solution. The tiny crater would gradually expand and form quasi-lens array. After ultrasonic treatment, relatively smooth lens array could be obtained. In addition, the curvature radius, aperture and filling factor of the lens array can be controlled by adjusting the pulse power, radiation times and etching time of Fem to second laser.

Zang et al. [73] used Fem to second laser direct writing technology to manufacture a high-quality three-dimensional artificial compound eye with no distortion and wide field of view. The artificial compound eye they made has a hexagonal shape, and the filling rate is close to 100%. Compared with a single lens, the distortion of the imaging is effectively reduced. Its field-of-view (FOV) without distortion can be controlled in the range of 30\(\mathrm{{}^\circ}\) to 90\(\mathrm{{}^\circ}\).

Zhu et al. [74] used a Fem to second laser to bombard the surface of optical glass with radiation pulses, and then used hydrochloride acid solution and ultrasonic technology to treat the glass substrate to prepare a lens array with a negative focal length. On the poly methyl methotrexate (PMMA) film, a PMMA film lens array was obtained, which was attached to the spherical curved surface to prepare an artificial compound eye. Fem to second laser additive manufacturing is a multi photon nonlinear absorption reaction that occurs when the Fem to second laser interacts with the material. The irradiated area will initiate a photo polymerization reaction; the non-irradiated area will not undergo a polymerization reaction, enabling the preparation of complex three-dimensional structures.

Xia et al. [75] spin-coated a layer of non-organic composite photo resist material (Armorer) on a flexible substrate, and used a Fem to second laser beam to irradiate the photo resist surface with precise pulses. The spherical curved surface of the lens array is laminated to prepare a three-dimensional bionic artificial compound eye. The Fem to second laser processing method to prepare the lens array has the advantages of short production cycle, simple process and good optical performance. However, the price of its equipment is high, the processing efficiency is low, and it is difficult to produce massively.

Stencil imprint is a method of transferring an existing structure onto a target surface. Usually, the lens array is prepared by mold forming. Imprinting is a method of transferring existing structures on a template to a target surface and can be used to create lens arrays [76]. Embossing technology can be divided into mechanical embossing, hot embossing, ultraviolet embossing according to different principles. Mechanical embossing is to use mechanical pressure directly on the target surface to press the micro structure. Hot embossing is to use a mold to obtain the lens array structure by taking advantage of the material’s characteristics of softening and deformation at higher temperatures [77]. Ultraviolet lithography is to inject liquid UV-curable polymer material into the mold, and then use ultraviolet light to cure, demolishing after forming lens array.

Zhu et al. [78] used the drosophila compound eye as a mold, and dipped the drosophila compound eye into PDMS solution. After curing and peeling the PDMS, the morphology drosophila compound eye was copied. Then PDMS was used as the mold and UV curing optical adhesive NOA78 was used as the material. An artificial compound eye with almost the same morphology as drosophila compound eye was successfully prepared by ultraviolet lithography [79 ].

Zhang et al. [80] prepared a layer of PS micro spheres on the surface of glass substrate by using the lifting method, injected PDMS solution onto the surface of PS micro spheres, and then cured and transferred into the mold. The prepared PDMS mold injected PMMA solution into the mold [81]. After curing by PMMA and stripping the template, a flexible PMMA thin film lens array is prepared. Stencil lithography is a kind of lens array technology which can be used in mass production, but the surface shape and quality of lens are damaged during the process of stencil stripping.

The hydrophilic and hydrophobic coating regions (hydrophilic and hydrophobic pattered substrates) are obtained by regionally regulating the surface and surface energy of the material [82]. The polymer liquid is then selectively whetted by coating or pulling. Under the action of surface tension, the hydrophilic region aggregates polymer droplets and eventually solidifies to form lens arrays. At present, researchers have many methods to prepare hydrophilic and hydrophobic patterned substrates [83].

Feng et al. [84] coated and solidified a layer of Fluoroscope (1-Butenyl vinyl ether) polymer (CYTOP) on a rough SIOX surface and used copper as a mask. CYTOP was etched by oxygen plasma, the mask was removed, and CYTOP was annealed at 230\(\mathtt{{}^\circ\!{C}}\) to obtain a hydrophilic and hydrophobic patterned substrate. The liquid was selectively whetted on a hydrophilic and hydrophobic patterned substrate to form an array of micro droplets. Mihailov and Lazare [85] steamed and plated a layer of hydrophobic material tired fluorocarbon-n-octal orthodoxy silage (POTS, 1H, 1H, 2H, 2H-Tridecafluoro-n-octyltriethoxysilane) on glass substrate. AZ9260 photo resist is coated on a hydrophobic glass substrate. After photo lithography, a circular array of photo resist layer is left on the glass substrate, and the glass substrate is treated with oxygen plasma [86]. The area covered by photo lithography retains its watt ability. The area not covered by photo resist becomes hydrophilic due to the action of plasma. Finally, solvent is used to remove the circular array photo resist pattern on the glass substrate to obtain hydrophilic and hydrophobic pattered surface [87]. The micro droplet lens array is formed after the surface is coated with liquid. Hydrophilic and hydrophobic effect method is an efficient, rapid and controllable method to fabricate lens arrays [88]. According to the principle of preparation, the preparation of common lens array can be divided into the effect of surface tension assisted method (ink jet printing, resist heat melting method, etc.), energy beam assisted method (Fem to second laser etching processing, two-photon Fem to second laser processing, etc.) and mechanical method of cold and hot working (such as super precision machining method, template stamping method, etc.) [89].

Electioneering is an electric field-based method for fabricating lens arrays. The manufacturing principle of the method is to place the liquid polymer on the surface of the solid medium in an electric field, and use the effect of the electric field on the liquid polymer to change the contact angle of the liquid polymer on the solid surface [90].

Florian et al. [91] introduced a method suitable for fabricating large-area lens arrays. The method begins by mechanically pressing a micro well array template onto an optical substrate coated with a polymerization liquid. A voltage is applied across the conductive template and the substrate on which the conductive indium tin oxide is deposited, creating an electric field force. This electric force acts on the liquid-gas interface in each micro pore [92]. The structure of the micro-hole array template results in an in homogeneous electric field force, which reaches a maximum value at the hole wall and a minimum value at the center of the hole, so that the dielectric liquid in the micro-hole is deformed into a concave surface, the curvature of which depends on the applied voltage [93]. Using this method, a concave lens array with optical functions can be directly manufactured, or a convex lens array can be manufactured by over molding the concave structure as a template [94].

The integration principle of the micro lens array is briefly introduced and its development history is reviewed, and the preparation method of the micro lens array is emphatically introduced. Among the commonly used fabrication techniques, inkjet printing, hot melt reflow and chemical vapor deposition are low-cost and generally applicable economical methods; laser direct writing and screen printing techniques can achieve rapid fabrication of large-scale micro lens arrays, but The processing accuracy is limited; lithography and photo polymerization techniques are used to prepare high-precision micro lens arrays, but the cost is high and the process is cumbersome; mechanical processing and chemical etching methods, as supplementary means for specific needs, can also quickly realize the micro lens array. preparation. Then, the applications of micro lens arrays in imaging sensing, luminescence, display and photovoltaic fields are summarized. micro lenses and their arrays play an important role in various fields. The future development trend of micro lens arrays must be miniaturization, intelligent ionization and integration. According to the above summary, starting from the application requirements of micro lens array, the future development is projected, as follows.

At present, there are many studies on flat micro lens arrays and they are widely used. However, the topic of preparing large-scale micro lens arrays on spherical or free-form surfaces needs to be further explored, and multiple issues such as reasonable arrangement of the array and optical crosstalk need to be considered. Carry out optical theoretical research on free-form surface micro lens array, so as to guide its preparation process and explore its application potential.

The micro lens array originated from the natural compound eye system, but as far as the current development is concerned, it still needs to be further improved. It can be considered to analyze and study the superimposed compound eye system, and design a multi-layer or even superimposed micro lens array to achieve a larger field of view, better imaging performance and a more compact structure of the miniature artificial compound eye camera, which will surely be used in advanced imaging and machine vision. etc. have made great progress.

The development of new solution-processed semiconductor materials such as quantum dots, perquisites, and conjugated polymers provides new material options for the preparation of micro lens arrays. How to combine the above-mentioned new microelectronic materials with micro lenses to achieve higher performance The devices and application systems are also key frontier topics that need to be paid attention to. In conclusion, the fabrication of micro lens arrays requires a combination of materials and micro-nana fabrication processes, and how to combine materials and fabrication techniques is still the focus of future attention. Although there is a certain research foundation in the preparation and application of micro lens arrays in China, there is a lack of systematic engineering research and industrial development, which needs to be further strengthened.

The experimental data used to support the findings of this study are available from the corresponding author upon request.

The authors declared that they have no conflicts of interest regarding this work.

There is no specific funding to support this research.