In today’s era, the rapid development of artificial intelligence is transforming warehousing and logistics by enhancing efficiency and reducing labor costs. In this paper, we first employ a least squares support vector machine to develop an inventory prediction model for warehousing logistics, accurately forecasting inventory values. Next, we design an automated logistics and warehousing architecture that facilitates seamless data transfer and information feedback. Finally, this architecture is used to build a comprehensive inventory management model. Our analysis shows that the AI-based prediction nearly matches the actual inventory value (229 vs. 230) and achieves an inventory turnover rate of 5 times per month, which significantly reduces backlog and improves overall management efficiency and user satisfaction.

In the era of rapid development of information technology, artificial intelligence technology is gradually developing and maturing, which has caused a corresponding impact and change on the logistics and warehousing industry. The traditional logistics warehousing industry mainly utilizes manual recording and management of goods, which is difficult to ensure the accuracy and completeness of the goods and is less efficient, so it is necessary to introduce artificial intelligence technology to facilitate the management of logistics warehousing [5]. Artificial intelligence technology, including big data analysis, machine learning and deep learning and other technologies, can realize the prediction and management of the inventory of warehousing logistics, and can accurately capture the changes and status of the inventory, while the operation is simple, which improves the efficiency of the operation [9,2]. Therefore, the use of artificial intelligence technology to predict and manage the inventory of warehousing logistics not only improves the accuracy and speed of prediction, but also reduces the cost and risk of inventory, combines warehousing logistics and artificial intelligence, promotes the development of artificial intelligence and warehousing logistics, and also provides a reference for the subsequent related fields [19,22].

In order to be able to discuss in depth the application of artificial intelligence technology to warehousing logistics, this paper firstly utilizes the least squares support vector machine to establish a prediction model for the inventory of warehousing logistics, and predicts the value of the inventory in warehousing logistics according to the model. Second, the design of logistics warehousing automation architecture, which is divided into five parts: user layer, front-end control layer, back-end service layer, data persistence layer and data storage layer, through the interaction between the different layers, to complete the transmission of data and user information request results feedback. Finally, according to the established architecture to form a detailed warehousing logistics inventory management model, including supply management, order management and incoming management, and analyze the different interfaces, so as to transfer data and information. More accurate management of goods, so that it can capture the quantity and changes in goods in a timely manner, reduce the loss of goods, improve the efficiency of management, reduce labor costs, reduce the backlog and accumulation of goods. Artificial intelligence can replenish goods in time, improve user satisfaction, and make the operation of warehousing and logistics more convenient and simple.

In the use of artificial intelligence technology to predict and manage logistics inventory, Wang et al. [17]analyze artificial intelligence technology and apply artificial intelligence in the management of logistics and inventory prediction to predict the inventory of warehouse logistics in order to replenish the stock in time. And the management of warehouse logistics is carried out to make the management of warehouse logistics more convenient and rapid and reduce the error rate. According to the experiment, it can be concluded that the inventory value predicted by artificial intelligence technology is similar to the actual value, which can make a reasonable prediction of the inventory of warehouse logistics, and the management of warehouse logistics is more perfect. Han et al. [7] analyzed the demand of warehouse logistics, and according to the need to establish a prediction model by using BP neural network, to predict the inventory of the logistics, and to get the inventory in warehouse logistics. And intelligent management of warehouse logistics is carried out to improve the efficiency of management. Model testing of the BP neural network approach, through the test results of the BP neural network predicted inventory value is more accurate, can be timely replenishment of inventory, and inventory management is better, improving the efficiency of warehouse management. Bruzda et al. [1] analyze and discuss the process and management of warehouse logistics, and empirically compare the calculation of the demand for a multi-step quartile prediction of the various approaches which is utilized to forecast and manage inventory in warehouse logistics. The forecast can establish a model of production planning and inventory management in the logistics system optimized according to the cyclic service level method, and integrate different econometric methods and models into it to forecast the inventory of warehouse logistics and improve the accuracy of the forecast. According to the experiments, the quantile prediction method can accurately predict the inventory in warehousing logistics, with a small difference from the actual value, and it can manage the logistics inventory and improve the efficiency of logistics operation. Zhou et al. [21] conducted an in-depth research and analysis of logistics inventory optimization using a multilayer feed-forward neural network approach, and conducted joint modeling of logistics, inventory and pricing to establish a stochastic inventory decision model based on nodal logistics forecasting. And through the inventory optimization solved the management and prediction of warehousing logistics, accurately derived the inventory of logistics, which can be replenished in a timely manner, improving the accuracy and efficiency of logistics goods management and making logistics management easier. Sert et al. [14] designed a complex system approach based on the downscaling method to optimize the logistics network, which describes and analyzes the logistics and unfolds the inventory of the logistics prediction and get the corresponding prediction value. At the same time, it can set up the corresponding logistics management structure according to the results of the description, manage the goods of logistics, record the import and export of goods, and facilitate the operation of logistics. According to the experiments, the predicted logistics inventory in this way is more accurate, and the response speed is faster, avoiding users waiting for a long time, and improving the efficiency and accuracy of logistics management. Tang et al. [15] designed a digital twin framework, which combines a logistics warehouse and a roulette wheel genetic algorithm, in order to predict the inventory of logistics. And use the digital framework to simulate the scene of logistics management, set the appropriate logistics management model, optimize the inventory of logistics, can record the situation of goods in time, with the function of query, so as to improve the efficiency of logistics management, make the operation of warehousing and logistics more convenient, and reduce costs. According to the experiment, it can be concluded that the model established in this way, the prediction effect is better and the accuracy rate is higher. He et al. [8] use the neural network algorithm and gray prediction based on the way to simulate and calculate the warehousing logistics, to predict the value of the inventory in the warehousing logistics, and through the simulation results, they design a model of logistics management, to carry on the intelligent management of the goods, and record the goods’ entry and exit in a timely manner, to improve the efficiency of logistics management and reduce the cost of labor. The test of this method can be concluded that the predicted value and the actual value are more similar, which can be replenished in time, and the operation of the management of goods is more simple, convenient to use and operate.

In order to be able to better predict the inventory value of warehouse logistics, the least squares support vector machine is used to predict the inventory, so as to get the accurate inventory value [13,11]. The least squares support vector machine mainly converts the original spatial inequality problem into the problem of feature space using a nonlinear way, which can improve the generalization degree of the model using the way of minimizing the structural risk, reduce the probability of the model entering the local minima, and improve the training speed of the model.

The training set consisting of \(N\) sample data is set to be denoted by \(\left\{x_{k} ,y_{k} \right\}_{k=1}^{N}\), the input data is denoted by \(x_{k} \in R^{m}\), and the output data is \(y_{k} \in R\). The function fitting problem can be derived based on the training set of the set data as shown below: \[\label{GrindEQ__1_} {\mathop{\min }\limits_{w,e}} \left(w,e\right)=\frac{1}{2} w^{T} w+\frac{1}{2} \gamma \sum _{k=1}^{N}e_{k}^{2} \; s.t.\; y_{k} =w\varphi \left(x_{k} \right)+b+e_{k} ,k=1,\cdots ,N , \tag{1}\] where \(\varphi \left({\rm \cdot }\right)R^{m} \to R^{m_{k} }\) represents the process of mapping the input data from the space \(R^{m}\) to the high-dimensional feature space \(R^{m_{k} }\), with \(w\in R^{m_{k} }\) representing the weighting vector, and the penalty coefficient error is denoted as \(y\), where the \(y>0\) error variable is denoted by \(e_{k} \in R\), and the bias value of \(R\) is denoted by \(b\in R\).

The optimization result of the above equation is transformed to the dyadic space, and according to the result the fitting model of least squares support vector machine is obtained as follows: \[\label{GrindEQ__2_} y\left(x\right)=\sum _{k=1}^{N}\alpha _{k} K\left(x_{k} ,x\right)+b , \tag{2}\] where \(k\) denotes the support vector, \(K\left(x_{i} ,x_{j} \right)\) is called the Gaussian kernel function, and the specific form of the generalized Gaussian kernel function is as follows: \[\label{GrindEQ__3_} K\left(x_{i} ,x_{j} \right)=\exp \left(-\left\| x_{j} -x_{i} \right\| ^{2} /\sigma ^{2} \right) . \tag{3}\]

Parameters \(\alpha _{k}\) and \(b\) in the least squares support vector machine are solved for the linear variance as shown below: \[\label{GrindEQ__4_} \left[\begin{array}{cc} {0} & {\Pi ^{T} } \\ {\Pi } & {Z+\gamma ^{-1} I} \end{array}\right]\cdot \left[\begin{array}{l} {b} \\ {a} \end{array}\right]=\left[\begin{array}{l} {0} \\ {y} \end{array}\right] , \tag{4}\] where \(I\) represents the unit matrix, \(y\) is used to represent the penalty factor, \(y=\left[y_{1} ,\cdots ,y_{n} \right];\Pi =\left[1,\cdots ,1\right]^{T} ;\alpha {\rm =}\left[\alpha _{1} ,\cdots ,\alpha _{n} \right]^{T} ;Z_{k,t} =K\left(x_{k} ,x_{t} \right)\).

In order to accurately compute the above linear equations, set \(\Omega =Z+\gamma ^{-1} I,A=\Omega ^{-1}\), and \(B=\left(\Pi ^{T} \Omega ^{-1} \right)/\left(\Pi ^{T} \Omega ^{-1} \Pi \right)\), the specific equations are converted to: \[\label{GrindEQ__5_} \left. \begin{array}{l} {b=By} \\ {a=A\left(y-By\right)} \end{array}\right\} . \tag{5}\]

The parameters and models in the least squares support vector machine are derived based on the above process, which facilitates the subsequent construction of the forecasting model to produce accurate inventory forecasts.

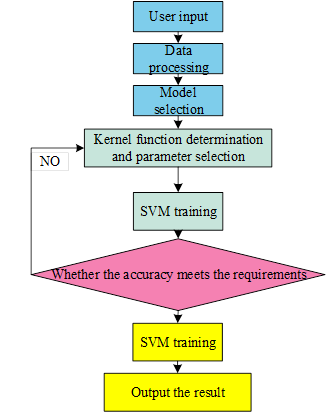

In order to be able to accurately and comprehensively predict the information of inventory in warehousing and logistics, and to reduce the probability of information loss, the way of predicting the inventory information needs to meet the conditions of small samples, so as to improve the accuracy of inventory prediction. The demand occurrence factors as input, the demand as output, the establishment of inventory prediction model based on least squares support vector machine, least squares support vector machine inventory prediction model shown in Figure 1, as follows:

(1) When inputting the inventory information, the database form input by the user needs to be input in the format of doc, .xls or SQLserver, so as to avoid the inconsistency of the input format, which will affect the prediction results.

(2) The model will convert the input sample data into a form that conforms to the support vector machine and normalize the data based on the user’s choice before prediction.

(3) Factors related to warehouse logistics inventory demand are found and incorporated into the prediction model as a way to improve the accuracy of the prediction.

(4) Because the inner product kernel function in the least squares support vector machine differs, resulting in different prediction effects of the least squares support vector machine, which will change with the parameters of the inner product kernel function, so it is necessary to select the kernel function and the parameters of the kernel function through the methods of cross-checking and lattice searching, and the user can make adjustments according to the needs.

(5) Input the sample data and the values of relevant influencing factors into the model, train the input data using the selected support vector machine model and kernel function, and compare the training accuracy. If the training accuracy meets the standard, it constitutes a complete prediction model and proceeds to the next step, otherwise it is necessary to repeat the operation of step (4) to further optimize it.

(6) The user independently selects the number of steps for prediction, and calls the prediction model obtained in step (5) for prediction.

(7) The obtained warehouse logistics inventory prediction results are output.

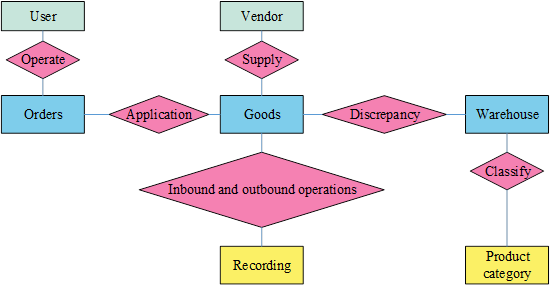

From the above steps to complete the prediction of warehousing logistics inventory, to get an accurate prediction value, in order to be more convenient management of warehousing logistics, logistics management needs to be carried out, set up the relevant management structure [4,18]. The logistics management structure is divided into five levels, specifically the user layer, the front-end control layer, the back-end service layer, the data persistence layer and the data storage layer, Figure 2 shows the logistics and warehousing automation entity. Specifically as follows:

(1) The user management layer is mainly used to manage user-related information, including user registration, login and query functions. The user management layer can interact with the front-end control layer so as to get the information sent by the user, and return the results after the back-end service layer and data persistence layer, which can realize the management and entry of employee information.

(2) The front-end control layer is mainly used to manage the interaction and information transfer between users and data, and through the information interaction with the user management layer, the user’s request information can be input to the back-end service layer. And the corresponding interface is utilized to return the obtained data to the interface.

(3) The back-end service layer mainly handles the requests sent by the front-end and completes the modularization of the model’s functions by using cutter-oriented programming to improve the scalability and maintainability of inventory management.

(4) The data persistence layer mainly manages and manipulates the database, completes database-related additions, deletions, modifications and checking operations, and utilizes XML configuration files to map the database table structure and operation information. This layer can interact with the back-end service layer to obtain data access functions and manage data.

(5) Data storage layer is to store the data, using physical storage to save the input data permanently, to ensure the reliability of the data, and this layer can interact with the data persistence layer to complete the read and write operations on the data.

Since the management model is composed of multiple modules, the modules are the basic units in the model and need to be represented and connected using relationships.

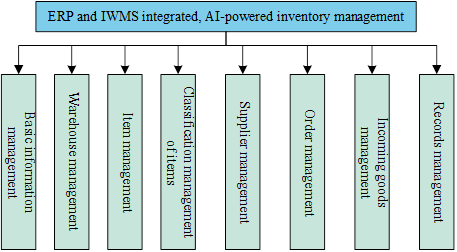

The architecture of warehouse management is constructed according to the above process, and in order to be able to manage warehouse logistics inventory more accurately and conveniently, artificial intelligence technology is used to establish a detailed management model. This includes supply management, order management and incoming management, in order to help the logistics and warehousing heating company to be able to efficiently manage the warehouse logistics, reduce the error rate caused by manual labor, and improve the efficiency of the operation [10,6]. Figure 3 shows the functional module of the AI inventory management system, which builds the AI warehouse inventory management module according to the automated system architecture to make timely records of the needs of the goods such as outgoing, incoming and supplying, so as to reduce the loss of goods. When constructing the warehouse inventory management module, it is necessary to ensure that the interface connecting different modules is complete and consistent, so that more modules can transfer information between them and realize normal interaction. Because the warehouse system and enterprise resource system need to interact with each other and information transfer, so the internal and external parts of the warehouse need to be synergized. In order to realize this operation, the consistency and shareability of interfaces are generally used, the consistency of data mainly refers to the consistency of data exchanged between the warehouse system and the enterprise resource system, and data sharing is the data between the warehouse system and the enterprise resource system to share each other’s data, so as to improve the efficiency of the warehousing and logistics management, and reduce the cost [20,16].

Classification of the interface used in warehousing logistics inventory management can be divided into two types, as follows:

(1) Inventory interface is mainly input to the warehouse logistics data transmission and exchange, the use of the corresponding protocols for data retrieval and feedback user requests, record information and location of the goods. And acceptance of goods and acceptance, in order to facilitate the inventory information on warehousing logistics query, reduce the rate of loss of goods, improve the efficiency of warehousing logistics management.

(2) Out of the warehouse interface mainly refers to the warehouse logistics management system and enterprise resource management system needs to use the interface to complete the data transmission work, to achieve data interaction. Under normal circumstances, the enterprise resource management system issued by the warehouse order, through the HTTP protocol will be transmitted to the warehouse logistics management system. If the warehouse logistics management system needs the outbound operation, it will use the HTTP protocol and data retrieval to request the outbound order from the enterprise resource management system [3].

According to the above interface, the different modules of inventory management can be connected, transferring data between each other, so as to ensure that the import and export of goods and query operations can be run normally, and can be recorded in a timely manner on the goods. In this way to complete the management of goods, improve the efficiency and accuracy of inventory management in warehousing logistics, reduce the backlog and loss of goods, and make the operation of warehousing logistics easier.

In order to accurately test the effect of artificial intelligence technology on logistics inventory prediction and management, it is necessary to prepare the corresponding equipment, choose a suitable site as the experimental site, and build a data acquisition system to collect information on warehousing logistics. Debugging of the corresponding tools and equipment to ensure that the equipment is in good condition, adjusting the parameters of the equipment, so that it meets the test requirements, does not affect the testing process, to ensure the accuracy of the experiment, the test equipment parameters as shown in Table 1. The data processing equipment includes a memory capacity of more than 128GB and a storage capacity of more than 2TB. Barcode scanning speed is greater than 100 times / sec, endurance of more than 8 hours.

| Equipment Category | Parameter | Numerical |

| Data processing equipment | CPU | \(\mathrm{>}\)24 cores |

| Memory Capacity | \(\mathrm{>}\)128GB | |

| Storage Capacity | \(\mathrm{>}\)2TB | |

| Data Acquisition Equipment | Operating Frequency | 860-960MHz |

| Recognition distance | \(\mathrm{>}\)5km | |

| Reading speed | 100-1000/s | |

| Barcode Scanning | Scanning speed | \(\mathrm{>}\)100 times/second |

| Recognition accuracy | \(\mathrm{>}\)99% | |

| Connection method | USB | |

| Automated Guided Vehicles | Maximum load | \(\mathrm{>}\)500kg |

| Endurance | \(\mathrm{>}\)8 hours | |

| Maximum speed | 0.5-2m/s |

Inventory prediction test is mainly used to measure the accuracy of the model for inventory prediction, if the model predicts the value and the actual value of inventory results are similar, then it shows that the model’s prediction ability is stronger, the results are more accurate, and it can reduce the backlog of inventory or out-of-stock situation. If the difference between the predicted value of the model and the actual value of the inventory is large, it means that the predictive ability of the model is weak, and it is difficult to accurately predict the results of the remaining inventory, so that it is not possible to replenish the inventory in time. Therefore, the model’s inventory prediction needs to be tested, and Table 2 shows the results of inventory prediction by different techniques.

It can be concluded that at the time of the first prediction, the AI technology had a value of 229, the IoT technology had a value of 210, the blockchain technology had a value of 240, and the actual value of the inventory was 230. While the third prediction had a value of 232 for IoT technology, 256 for blockchain technology, and equal actual values for AI technology and inventory were both 245. In the fifth prediction, IoT technology had a value of 217, blockchain technology had a value of 223, and AI technology had a value consistent with the actual value of 220. This shows that the value predicted by artificial intelligence technology is more accurate, almost the same as the actual value, and can accurately derive the value of logistics inventory, which can be replenished in a timely manner and reduce the error rate. The value of the Internet of Things technology and blockchain technology and the actual value of the difference is more, it is difficult to accurately predict the inventory value of warehousing and logistics, can not be timely replenishment, the error rate is higher, is not suitable for wide application.

| Ordinal number | Actual value of inventory | Artificial intelligence technology predictions | Internet of things technology forecast | Blockchain technology predictions |

| 1 | 230 | 229 | 210 | 240 |

| 2 | 130 | 131 | 122 | 110 |

| 3 | 245 | 245 | 232 | 256 |

| 4 | 320 | 319 | 330 | 345 |

| 5 | 220 | 220 | 217 | 223 |

| 6 | 350 | 348 | 337 | 367 |

| 7 | 390 | 389 | 410 | 400 |

| 8 | 310 | 309 | 323 | 290 |

| 9 | 278 | 276 | 297 | 267 |

Inventory turnover efficiency test is mainly used to measure the efficiency of warehousing logistics management, usually, the higher the inventory turnover rate, indicating that the higher the efficiency of warehousing logistics management, can be quickly and easily to organize the inventory. The goods in and out of the record is complete, reducing the backlog of goods, the lower the inventory turnover rate, the lower the efficiency of inventory management, can not record the goods in and out of the timely record. The turnover efficiency of inventory management is tested, and the results of the inventory turnover efficiency test are shown in Table 3. It can be seen that the artificial intelligence calculation set up the logistics management method is more effective, the number of inventory turnover rate is better. In the month of January, the inventory turnover of AI was 3 times/month, IoT technology was 2 times/month and blockchain technology was 2 times/month. In February, the inventory turnover rate was 5 times/month for AI, 2 times/month for IoT technology and 3 times/month for blockchain technology. While in March, the inventory turnover of AI was 3 times/month, IoT technology was 1 time/month and blockchain technology was 1 time/month. This can show that the logistics management method of AI technology is more realistic, which can record and process the goods in time and ensure that the goods are recorded in and out. And it can reduce the backlog of goods, make the management and operation of warehousing logistics more convenient and simple, improve the efficiency of logistics management and reduce costs.

| Months | Artificial intelligence technology predictions | Internet of things technology forecast | Blockchain technology predictions |

| 1 | 3 times/month | Secondary/month | 2nd order/month |

| 2 | 5 times/month | Secondary/month | Tertiary/month |

| 3 | 3 times/month | Primary/month | Primary/month |

| 4 | 5 times/month | 2nd/month | 1st order/month |

| 5 | 6 times/month | Tertiary/month | 5th/month |

| 6 | 5 times/month | Secondary/month | Tertiary/month |

| 7 | 3 times/month | Primary/month | 2nd/month |

| 8 | 5 times/month | Secondary/month | Tertiary/month |

| 9 | 3 times/month | 2nd/month | 1st order/month |

Response speed test is mainly to measure the speed of the model to predict the inventory quantity, the faster the speed of the model’s response, it means that the model can feedback the predicted results in time, avoiding the user to wait for a long time, and it can capture the changes of the goods in time to reduce the occurrence of losses. So the response speed of the model needs to be tested, and Table 4 shows the results of the response speed test. It can be seen that the prediction speed of artificial intelligence technology is faster. At the first time, the response rate was 3s for AI, 5s for IoT technology and 6s for blockchain technology. The second time around, the response rate was 2s for AI, 5.5s for IoT technology, and 5s for blockchain technology. At the third time, the response rate was 5s for AI, 5.3s for IoT technology and 6.1s for blockchain technology. It can be concluded that the response speed of artificial intelligence technology is much faster than the other two, which reduces the user’s waiting time and improves the user’s satisfaction, and it can reflect the situation in the warehousing and logistics in a timely manner, which reduces the loss of goods, and it can be promoted for use.

| Ordinal number | Artificial intelligence technology response rate | Internet of things technology response rate | Blockchain technology response rate |

| 1 | 3s | 5s | 6s |

| 2 | 2s | 5.5s | 5s |

| 3 | 5s | 5.3s | 6.1s |

| 4 | 3s | 3s | 5.3s |

| 5 | 3.5s | 6s | 5.2s |

| 6 | 2s | 5.5s | 5s |

| 7 | 2.1s | 6.1s | 6s |

| 8 | 3s | 6.5s | 5.1s |

| 9 | 2.2s | 5.2s | 6.2s |

Order processing time is mainly a measure of the model in the processing of orders, orders from inbound to outbound between the length of time, if the length of time used is shorter, it shows that the model processing orders faster, can reduce the inventory backlog, in line with the user’s needs, to enhance the user’s satisfaction level. Then the processing time of the order needs to be tested, and the results of the order processing time test are shown in Table 5. The model established by artificial intelligence technology for order processing time is shorter, the first test in about 10s, while the other two ways to process the order is longer, respectively, in about 15s and 12s. This can show that the artificial intelligence technology processing speed is faster, meets the user’s expectations, reduces the accumulation of goods, reduces the waste of resources, so that resources can be reasonably utilized, and improves the operational efficiency of warehouse logistics management.

| Ordinal number | Artificial intelligence technology processing time | IoT technology processing time | Blockchain technology processing time |

| 1 | 10s | 15s | 12s |

| 2 | 9s | 12s | 13s |

| 3 | 10.1s | 14s | 13s |

| 4 | 8.7s | 12s | 11s |

| 5 | 9s | 11s | 12s |

In this paper, firstly, the least squares support vector machine is utilized to establish a prediction model to derive the value of inventory in warehousing and logistics. Secondly, it builds an automated architecture for logistics and warehousing, and utilizes the interaction between different layers to complete the transfer of data between them. Finally, a detailed inventory management model of warehousing logistics is composed according to the established architecture, so as to carry out inventory. The measurement ability is better. In the first prediction, the value of artificial intelligence technology is 229, and the actual value of inventory is 230, while in the third prediction, the actual value of artificial intelligence technology and inventory are equal to 245, which indicates that the predicted value of artificial intelligence technology and the actual value of the formation of smaller. The analysis of the turnover efficiency of AI technology shows that in the month of March, the inventory turnover rate of AI is 3 times/month, which is a high turnover efficiency and can avoid the backlog of goods. And the prediction speed of artificial intelligence technology is faster, in the first test, it can reach 3s role, which can respond to the user’s needs in time. In summary, it can be shown that artificial intelligence technology can timely arrive at the situation in warehousing and logistics, record the inventory of warehousing and logistics, reduce the cost and the loss of goods, and at the same time promote the development and progress of artificial intelligence technology.

Zhicheng Ma was born in Songyuan, Jilin. China, in 1996. He obtained a bachelor’s degree from Dongbei University of Finance and Economics in China and master degree from the University of Warwick. He currently working in the Yongsheng construction corporation. His main research direction is inventory management and supply chain planning.